Our Products

Quality Products

We are committed to providing our customers with high-quality packaging solutions that meet their specific needs. We have a strong track record of innovation and we are constantly looking for new ways to improve our products and services.

HDPE, PC, PP & PETG Bottles

HDPE, PC, PP and PETG Bottles are produced in continuous extrusion blow moulding & Intermittent Parison Blow moulding process where the semi molten thermo plastics will be formed by pressurized blow air in to the tubular form of plastic which called as Parison and take the shape of the aluminum or steel cavities.

HDPE, PC, PP & PETG Bottles

HDPE, PC, PP and PETG Bottles are produced in continuous extrusion blow moulding & Intermittent Parison Blow moulding process where the semi molten thermo plastics will be formed by pressurized blow air in to the tubular form of plastic which called as Parison and take the shape of the aluminum or steel cavities.

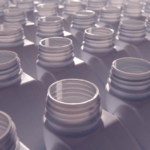

PET Preforms

PET preforms are produced for CSD, Bottled Water, Bulk water and Dairy & Juice bottles using different PET resins as per the package requirements.

IML Cups

The IML is part of a process in Injection molding and is a costeffective way to include information and graphics on plastic containers . With this technique, the label retains its integrity, no scratching or peeling and aesthetically, its print quality gives an exceptional and remarkable look.

IML Cups

The IML is part of a process in Injection molding and is a costeffective way to include information and graphics on plastic containers . With this technique, the label retains its integrity, no scratching or peeling and aesthetically, its print quality gives an exceptional and remarkable look.

PET Bottles

PET Bottles are produced in single stage or two stage process. In single stage process, preforms and bottles are produced in the same machine/ system which is called as Injection Blow Moulding (IBM) or Injection Stretch Blow Moulding (ISBM)

PET Sheet PS / PP Sheet

Thermoplastic like PET, PS, PP semi molten resin are fed through calendaring rolls & cooled enough to solidify as sheet in to required width and thickness. SPPS have monolayered PET sheet,3 layered PP and 4 Layered PS sheets.

Stretch Film

The Cast extrusion process is a continuous in which a thermoplastic material is melted and extruded through a flat die onto a chilled roll, where it is quenched and re-solidified in to desired thickness. And required width will be trimmed off before roll winding stations.

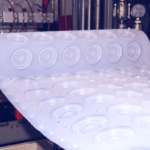

Thermoformed Cups

The principle behind thermoforming products is quite simple in theory. Heat a sheet of HIPS, Polypropylene, PET or similar plastic sheet or film and by process of vacuum and air pressure, pull the sheet down over a solid mould to obtain the desired shape.

HDPE, PC, PP & PETG Bottles

HDPE, PC, PP and PETG Bottles are produced in continuous extrusion blow moulding & Intermittent Parison Blow moulding process where the semi molten thermo plastics will be formed by pressurized blow air in to the tubular form of plastic which called as Parison and take the shape of the aluminum or steel cavities.

HDPE, PC, PP & PETG Bottles

HDPE, PC, PP and PETG Bottles are produced in continuous extrusion blow moulding & Intermittent Parison Blow moulding process where the semi molten thermo plastics will be formed by pressurized blow air in to the tubular form of plastic which called as Parison and take the shape of the aluminum or steel cavities.

PET Preforms

PET preforms are produced for CSD, Bottled Water, Bulk water and Dairy & Juice bottles using different PET resins as per the package requirements.

PET Bottles

PET Bottles are produced in single stage or two stage process. In single stage process, preforms and bottles are produced in the same machine/ system which is called as Injection Blow Moulding (IBM) or Injection Stretch Blow Moulding (ISBM)

IML Cups

The IML is part of a process in Injection molding and is a costeffective way to include information and graphics on plastic containers . With this technique, the label retains its integrity, no scratching or peeling and aesthetically, its print quality gives an exceptional and remarkable look.

IML Cups

The IML is part of a process in Injection molding and is a costeffective way to include information and graphics on plastic containers . With this technique, the label retains its integrity, no scratching or peeling and aesthetically, its print quality gives an exceptional and remarkable look.

PET Sheet PS / PP Sheet

Thermoplastic like PET, PS, PP semi molten resin are fed through calendaring rolls & cooled enough to solidify as sheet in to required width and thickness. SPPS have monolayered PET sheet,3 layered PP and 4 Layered PS sheets.

Thermoformed Cups

The principle behind thermoforming products is quite simple in theory. Heat a sheet of HIPS, Polypropylene, PET or similar plastic sheet or film and by process of vacuum and air pressure, pull the sheet down over a solid mould to obtain the desired shape.

Stretch Film

The Cast extrusion process is a continuous in which a thermoplastic material is melted and extruded through a flat die onto a chilled roll, where it is quenched and re-solidified in to desired thickness. And required width will be trimmed off before roll winding stations.